|

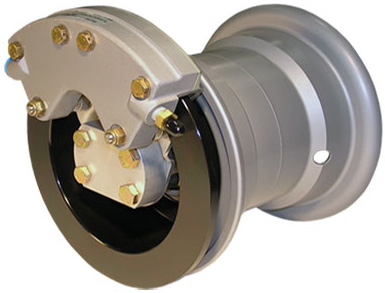

Grove Wheels and Brakes are precision engineered and manufactured to provide the highest quality and performance available in the aircraft industry. In order to achieve maximum performance for your particular aircraft, consider the following factors: 1. Size—Tire and axle size. Click on the wheel size in the left panel for appropriate listings. 2. Material—Grove wheels are manufactured in both aluminum and magnesium. Aluminum wheels are more corrosion resistant than magnesium, are less expensive, but weigh more. Both have the same strength and performance ratings. 3. Static Load Rating—Determine the static aircraft gross weight on each wheel. Select a wheel whose static load rating is at least this amount. 4. Braking Torque—A function of the hydraulic system pressure and total caliper piston area. Aircraft with oversized tires or with a larger than normal engine should consider brake calipers with more or larger pistons. 5. Kinetic Energy—One of the functions of the brake system is to absorb the heat energy developed during braking. The majority of this heat is absorbed by the brake disc. The larger the mass of the disc, the more heat energy it is able to absorb. A well designed brake system will provide adequate disc mass without excessive weight. The kinetic energy required to stop an aircraft is a function of the mass (weight) of the aircraft multiplied by the square of its landing speed. |

Calculate the kinetic energy for your aircraft by entering whole numbers

(no comma |